Z-355-6A DC Motor

-

This series of motor is newly developed medium sized DC motor since Z4 series small size DC motor, which adopts advanced design and polygonal lamination structure for stator framework, fully utilizing space effectively. The whole stator and rotor adopts solvent-free paint vacuum pressure immersion treatment (VPI), making winding with good moisture resistance ability and mechanical strength and the insulation and heat-conducting property is good. Stator magnet yoke, pole, armature core are all made by overlaying fine silicon steel plates. This series of motor has advantages of high efficiency and low noise, etc. The motors can operate when ambient temperature is -15℃~+40℃; the altitude ≤1KM; and monthly average air humidity ≤90% (If temperature is 25℃).This series of motor mainly applied in all kinds of industrial departments, such as metallurgical industrial rolling mill, metal cutting machine, paper-making, dyeing and weaving, printing, cement, plastic extrusion machines, etc.

| No. | Speed under rated Voltage UN (r/min) | Rated Power KW | Rated Current A | Eff. (%) | Max. Speed r/min | Excitation Power KW | Rotational Inertia kg.㎡ | Rated Torque N.m | ||||

| 220V | 330V | 440V | 550V | 660V | ||||||||

| 1 | 98 | 55 | 379 | 66 | 400 | 7 | 18.6 | 5360 | ||||

| 159 | 90 | 356 | 76.6 | 500 | 7 | 18.6 | 5406 | |||||

| 231 | 132 | 368 | 81.5 | 700 | 7 | 18.6 | 5457 | |||||

| 281 | 160 | 345 | 84.3 | 900 | 7 | 18.6 | 5438 | |||||

| 345 | 200 | 351 | 86.3 | 1050 | 7 | 18.6 | 5536 | |||||

| 2 | 133 | 75 | 476 | 71.6 | 400 | 7 | 18.7 | 5385 | ||||

| 231 | 132 | 494 | 80.9 | 700 | 7 | 18.7 | 5457 | |||||

| 283 | 160 | 432 | 84.2 | 900 | 7 | 18.7 | 5399 | |||||

| 356 | 200 | 420 | 86.6 | 1050 | 7 | 18.7 | 5365 | |||||

| 444 | 250 | 429 | 88.3 | 1200 | 7 | 18.7 | 5377 | |||||

| 3 | 189 | 110 | 645 | 77.5 | 500 | 7.1 | 18.7 | 5558 | ||||

| 280 | 160 | 579 | 83.7 | 850 | 7 | 18.7 | 5457 | |||||

| 382 | 220 | 570 | 87.1 | 1100 | 7 | 18.7 | 5500 | |||||

| 484 | 280 | 571 | 89.1 | 1400 | 7 | 18.7 | 5525 | |||||

| 547 | 315 | 530 | 90 | 1500 | 7 | 18.7 | 5500 | |||||

| 4 | 234 | 132 | 742 | 80.8 | 700 | 7.1 | 18.8 | 5387 | ||||

| 329 | 185 | 655 | 85.6 | 900 | 7.1 | 18.8 | 5370 | |||||

| 444 | 250 | 645 | 88.1 | 1200 | 7.1 | 18.8 | 5377 | |||||

| 561 | 315 | 637 | 89.9 | 1500 | 7.1 | 18.8 | 5362 | |||||

| 639 | 355 | 594 | 90.5 | 1500 | 7.1 | 18.8 | 5306 | |||||

| 5 | 281 | 160 | 868 | 83.8 | 850 | 7.1 | 19 | 5438 | ||||

| 429 | 250 | 860 | 88.1 | 1000 | 7.1 | 19 | 5565 | |||||

| 544 | 315 | 798 | 89.7 | 1500 | 7.1 | 19 | 5530 | |||||

| 657 | 375 | 753 | 90.5 | 1500 | 7.1 | 19 | 5451 | |||||

| 742 | 425 | 705 | 91.3 | 1500 | 7.1 | 19 | 5470 | |||||

0102030405060708

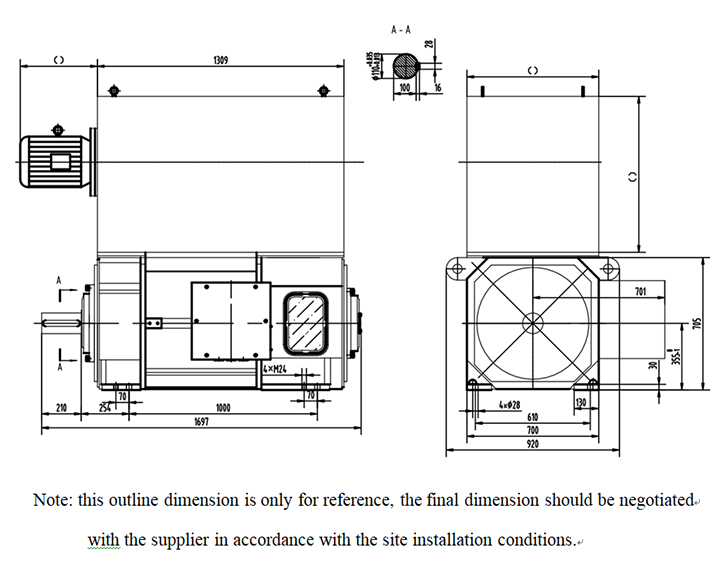

description1