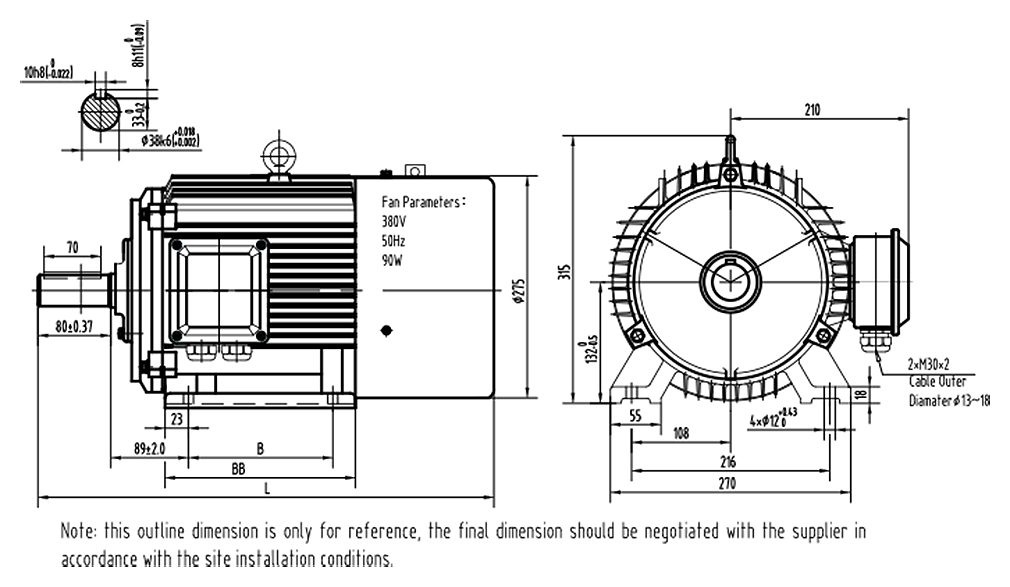

YVFE4 132S-2/4/6/8 IE4 VF 3-Phase Asynchronous Motor

-

Common faults and troubleshooting methods are as follows when this series of motor fails during the operating process.If the motor bearing is over heated, possible reasons are: 1) bearing failure; 2) improper filling of bearing grease or poor quality; 3) the coupling is asymmetric with the center or the pulley is not tight enough; 4) shaft and bearing are matched too loose or too tight; 5) the bearing is matched too tight with the end cap; 6) the end caps or bearing caps on both ends of the motor are not assembled properly. Relevant solutions are: 1) replace the bearing; 2) replace the grease with the filling capacity of 1/2~2/3; 3) calibrate the coupling or adjust belt tension; 4) spray metal if too loose and grind again if too tight; 5) insert steel sleeve in the end cover if too loose and process the bearing chamber if too tight; 6) reassemble the motor.If the motor has excessive temperature or smoke during operating, reasons maybe: 1) overload; 2) high ambient temperature; 3) low supply voltage or connection error; 4) single-phase operation of the motor; 5) poor ventilation; 6) stator winding earthing or turn-to-turn, interphase fault; 7) broken bar of squirrel cage rotor; 8) stator and rotor rubbing. In this condition, solutions as follows can be adopted: 1) detect the current of motor stator with tong-type ammeter. If overload, select a large motor or reduce the load; 2) lower the ambient temperature or reduce the load; 3) check the power supply, voltage and connection, reduce the load or stop; 4) check electrical connections to eliminate phase failure; 5) remove dirt and debris from air inlet and outlet; 6) check the stator windings, repair or replace them; 7) replace the rotor; 8) check assembly quality, bearing wear and so on.

| Type | Rated Power | Current/380V | Current/400V | Speed | Sync. Speed | Eff. | Power Factor | Locked torque | Locked current | Max. torque | Rated Torque | Moment of Inertia | No-Load Noise | Weight |

| kW | A | A | r/min | r/min | % | Cosφ | Rated Torque | Rated Current | Rated Torque | N•m | kg•m2 | dB(A) | Kg | |

| YVFE4-132S1-2 | 5.5 | 10.4 | 10 | 2945 | 3000 | 90.9 | 0.88 | 2 | 9.5 | 2.3 | 17.5 | 0.02 | 96 | 78 |

| YVFE4-132S2-2 | 7.5 | 14 | 13.3 | 2940 | 3000 | 91.7 | 0.89 | 2 | 9.5 | 2.3 | 23.9 | 0.03 | 96 | 84 |

| YVFE4-132S-4 | 5.5 | 11.4 | 10.8 | 1470 | 1500 | 91.9 | 0.8 | 2 | 9.5 | 2.3 | 35 | 0.06 | 86 | 89 |

| YVFE4-132S-6 | 3 | 7.2 | 6.9 | 970 | 1000 | 88.6 | 0.71 | 2 | 7.5 | 2.1 | 28.7 | 0.04 | 84 | 64 |

| YVFE4-132S-8 | 2.2 | 5.7 | 5.4 | 710 | 750 | 84.5 | 0.7 | 1.8 | 7.5 | 2 | 28.2 | 0.05 | 84 | 90 |

0102030405060708

description1