Y-355-2/4/6 High Efficiency Air Cooling 3 Phase Asynchronous Motor

-

Y series high voltage efficiency motor can be operated when the rated frequency is both 50HZ and 60HZ. As the utilization and size of motors are related to torque rather than power the theoretical power of single-speed motors increases linearly with supply frequency (and hence with speed), i.e. by 20 % from 50 Hz to 60 Hz.I2R winding-losses are dominant especially in small and medium sized induction motors. They basically remain constant at 50 Hz and 60 Hz as long as the torque is kept constant. Although windage, friction and iron loss, increase with frequency, they play a minor role especially in motors with a number of poles of four and higher. Therefore, at 60 Hz, the losses increase less than the 20 % power increase when compared to 50 Hz and consequently, the efficiency is improved.In practice, both 60 Hz and 50 Hz power designations of single-speed motors have to conform to standard power levels in accordance with IEC 60072-1 and local standards such as EN 50347. Therefore, an increased rating of motor power by 20 % is not always possible. However the general advantage of 60 Hz still applies when the motor design is optimized for the respective supply frequency rather than just re-rated. The difference in efficiency between 50 Hz and 60 Hz varies with the number of poles and the size of the motor. In general, the 60 Hz efficiency of three-phase, cage-induction motors in the power range from 0,75 kW up to 375 kW is between 2,5 percentage points to less than 0,5 percentage points greater when compared to the 50 Hz efficiency. Only large 2-pole motors may experience a reduced efficiency at 60 Hz due to their high share of iron, windage and friction losses.

| Type | Rated Power kW | Rated Current A | Rated Speed r/min | Eff. % | Power Factor Cosφ | Locked Torque | Locked Current | Max. Torque | Load moment of inertia Kg.m2 | Weight Kg |

| Rated Torque | Rated Current | Rated Torque | ||||||||

| Y-3551-2 | 220 | 26.8 | 2975 | 92.0 | 0.86 | 0.6 | 7.0 | 1.8 | 16 | 1810 |

| Y-3552-2 | 250 | 30.4 | 2975 | 92.1 | 0.86 | 0.6 | 7.0 | 1.8 | 18 | 1820 |

| Y-3553-2 | 280 | 33.9 | 2975 | 92.3 | 0.86 | 0.6 | 7.0 | 1.8 | 20 | 1854 |

| Y-3554-2 | 315 | 38.0 | 2975 | 92.7 | 0.86 | 0.6 | 7.0 | 1.8 | 22 | 1904 |

| Y-3555-2 | 355 | 42.7 | 2975 | 93.0 | 0.86 | 0.6 | 7.0 | 1.8 | 24 | 1950 |

| Y-3551-4 | 220 | 26.9 | 1485 | 92.5 | 0.85 | 0.8 | 6.5 | 1.8 | 77 | 1560 |

| Y-3552-4 | 250 | 30.6 | 1485 | 92.6 | 0.85 | 0.8 | 6.5 | 1.8 | 87 | 1605 |

| Y-3553-4 | 280 | 33.8 | 1485 | 92.7 | 0.86 | 0.8 | 6.5 | 1.8 | 96 | 1650 |

| Y-3554-4 | 315 | 37.9 | 1485 | 92.9 | 0.86 | 0.8 | 6.5 | 1.8 | 107 | 1710 |

| Y-3555-4 | 355 | 42.7 | 1485 | 93.1 | 0.86 | 0.8 | 6.5 | 1.8 | 89 | 1885 |

| Y-3556-4 | 400 | 48.0 | 1485 | 93.3 | 0.86 | 0.8 | 6.5 | 1.8 | 99 | 1935 |

| Y-3554-6 | 220 | 28.0 | 990 | 92.2 | 0.82 | 0.8 | 6.0 | 1.8 | 210 | 1670 |

| Y-3555-6 | 250 | 31.7 | 990 | 92.5 | 0.82 | 0.8 | 6.0 | 1.8 | 235 | 1725 |

| Y-3556-6 | 280 | 35.0 | 990 | 92.7 | 0.83 | 0.8 | 6.0 | 1.8 | 240 | 1905 |

0102030405060708

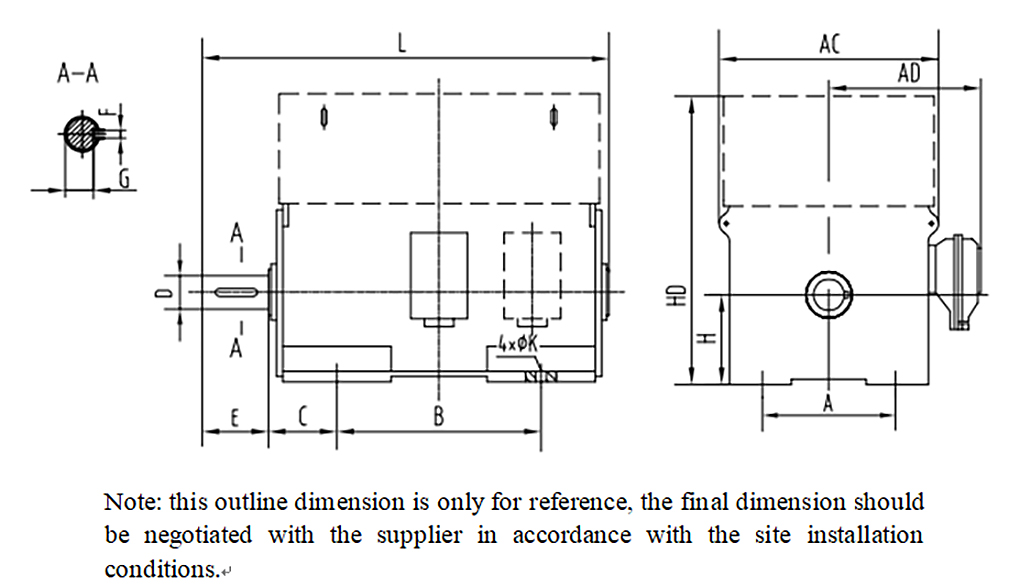

description1