| Item |

Parameter |

| Power supply |

Rated supply voltage |

three phase 380V ~ 480V |

| Allowed voltage fluctuations |

-15%~+10% |

| Rated supply frequency |

50/60Hz |

| Allowed Frequency Fluctuations |

±5% |

| Output |

Max output voltage |

Three-phase 380V~480V

Go after the input voltage |

| Max Output frequency |

500Hz |

| Carrier Frequency |

0.5 ~ 16kHz (automatic adjustment according to the temperature, and the adjustment range differs for different models ) |

| Overload capacity |

150% rated current 60s;

180% rated current 3s. |

| Basic Functions |

Frequency setting resolution |

Digital setting: 0.01Hz

Analog setting: max frequency × 0.025% |

| Control Mode |

Open Loop Vector Control (SVC)

V/F Control |

| Pull-in torque |

0.3Hz/150%(SVC) |

| Speed range |

1 : 200(SVC) |

| Speed Stabilizing accuracy |

±0.5%(SVC) |

| Torque boost |

Automatic torque boost

Manual torque increase 0.1% ~ 30.0% |

| V/F Curve |

Three ways:

linear type;

multi-point type;

N-th power V/F curve (n=1.2, 1.4, 1.6, 1.8, 2) |

| Acceleration and deceleration curve |

Linear or S-curve acceleration and deceleration;

Four kinds of acceleration and deceleration time.

Adjustable range 0.0~6500.0S |

| DC braking |

Frequency of DC braking: 0.00Hz ~ max frequency

Braking time: 0.0s ~ 36.0s

Braking action current value: 0.0% ~ 100.0% |

| Jogging control |

Jogging frequency range:0.00Hz ~ 50.00Hz

Jog acceleration- deceleration time:0.0s ~ 6500.0s |

|

Simple PLC, multi-stage speed operation |

Up to 16-stage speed operation via built-in PLC or control terminal |

| Built-in PID |

Implementing closed-loop control in process control applications |

| Overvoltage and overcurrent stall control |

Automatically limit current and voltage during operation to prevent fault shutdown due to frequent over-current and over-voltage |

| Fast current limiting function |

Reduce overcurrent fault shutdown to ensure the normal operation of the frequency converter |

| Control interface |

Digital input |

5 multi-function digital inputs.

One of which supports max 100kHz pulse input function |

| Analog input |

2 analog inputs.

Both supporting 0 ~ 10V or 0 ~ 20mA analog input, switch voltage or current input via jumper |

| Digital output |

2 open-collector digital outputs.

One of which supports max 100KHz square wave output |

| Analog output |

1 analog output.

Supporting 0 ~ 10V or 0 ~ 20mA analog output, switch voltage or current output via jumper |

| Relay output |

1-channel relay output, including 1 normally open contact, 1 normally closed contact |

| Standard communication interface |

1 channel RS485 communication interface |

| Expansion interface |

Function expansion interface |

Connectable to IO expansion card, PLC programmable expansion card, etc. |

| Operation panel |

LED digital display |

5-digit display of parameters and settings |

| Indicator light |

4 status indications, 3 unit indications |

| Button’s Function |

5 function buttons including 1 multi-function button. The function can be set via parameter P0 - 00 |

| Shuttle Knob |

Add, minus and confirm |

| Parameter copy |

Fast upload and download parameters |

| Protective function |

Basic protection |

Input and output phase loss, overvoltage, undervoltage, overheating, overload, overcurrent, short circuit, voltage and current limiting, fast current limiting and other protection functions |

| Environment |

Operation condition |

Indoor, no conductive dust and oil, etc. |

| Operating ambient temperature |

-10°C ~ +40°C (40°C ~ 50°C, derate 1.5% for every 1°C increase in temperature |

| Humidity |

Less than 95% RH, no condensation |

| Operating altitude |

No derating below 1000m, derate by 1% for every 100m elevation above 1000m

(<=1000m without derating,

>1000m with current derating 1% per 100m) |

| Ambient temperature for Storage |

-20℃ ~ +60℃ |

| Vibration |

Less than 5.9m/s² (0.6g) |

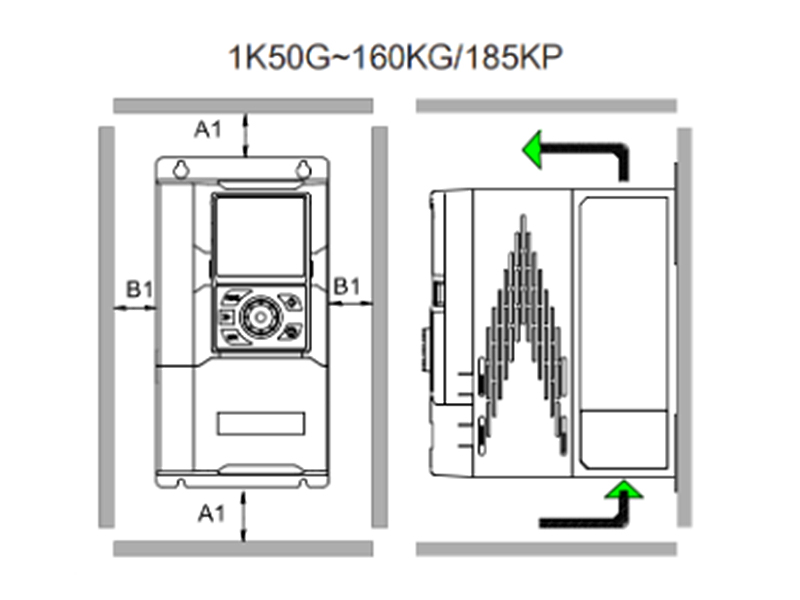

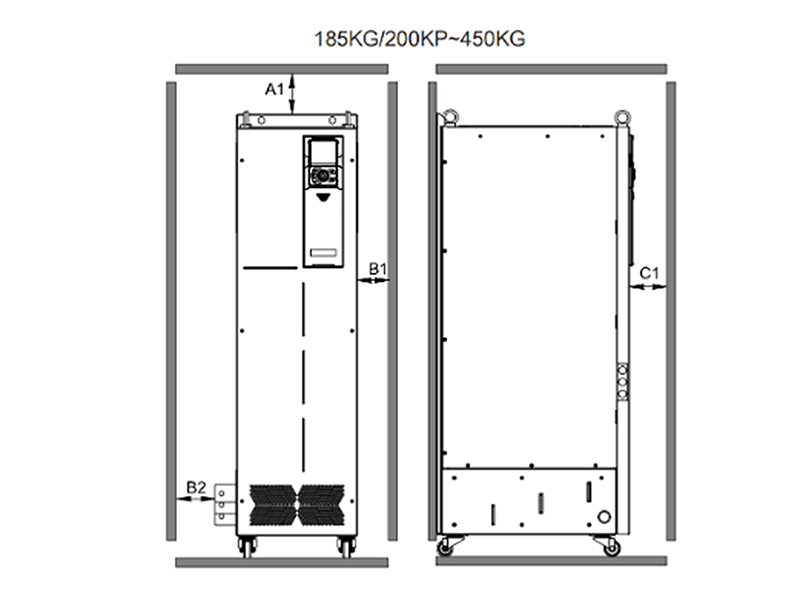

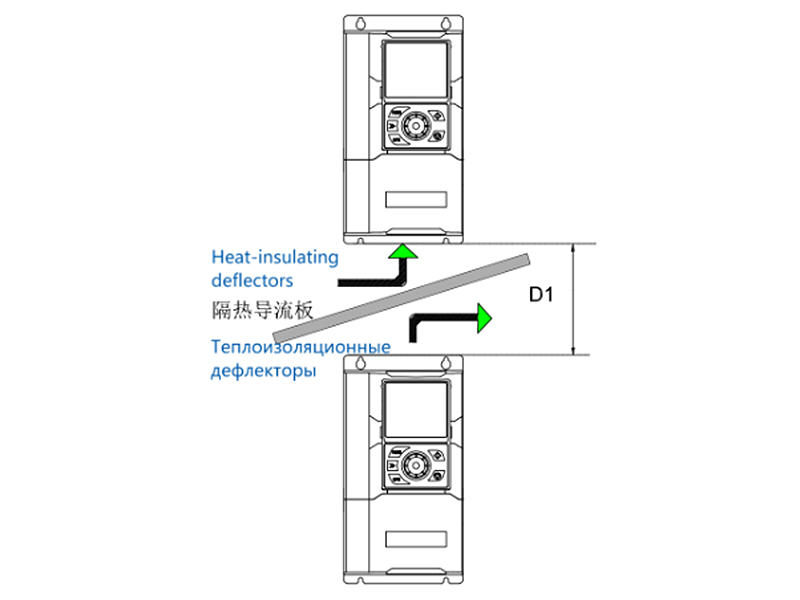

| Installation method

Mounting mode |

Wall-mounted or flush-mounted installation in the cabinet

(Need to choose the appropriate installation accessories) |

| IP degree of protection |

IP20 |