0102030405

The Comparison of Four Types of Mechanical transmission

2024-06-27 10:43:06

In the current four categories of transmission modes (mechanical, electrical, hydraulic and pneumatic), no power transmission is perfect.

Mechanical drive

1.Gear drive

Including: plane gear drive, space gear drive.

Advantages: Wide range of applicable circular speed and power; Transmission ratio accurate, stable, high efficiency; High reliability, long life; The transmission between parallel axes, intersecting axes at any Angle and alternating axes at any Angle can be realized.

Disadvantages: requires high manufacturing and installation accuracy; The cost is higher; Not suitable for long-distance transmission between two axes.

The names of the basic dimensions of the standard gear include top circle, root circle, index circle, touch number, pressure Angle, etc.

2. Turborod drive

It is suitable for motion and power between two vertical and disjoint axes of space.

Advantages: large transmission ratio; Compact structure size.

Disadvantages: large axial force; Easy to heat; Low efficiency; One-way drive only.

The main parameters of turbine shaft transmission are: modulus; Pressure Angle; Dividing circle of worm gear; Worm index circle; Leads; Number of worm gear teeth; Number of worm heads; Transmission ratio, etc.

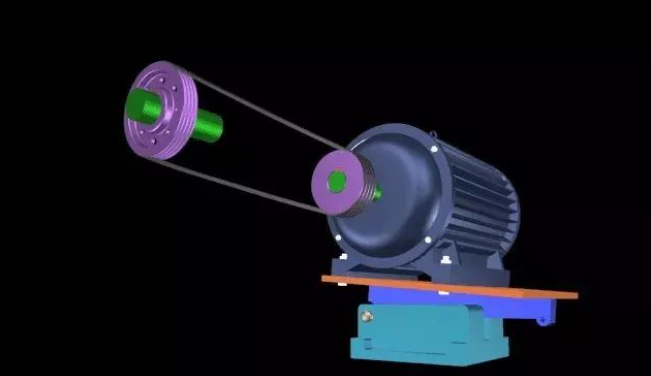

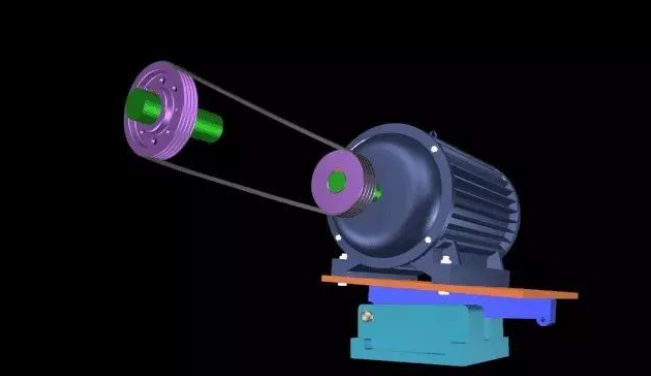

3. Belt drive

Including: driving wheel, driven wheel, ring belt.

It is used in cases where two axes are parallel in the same direction of rotation, called the concept of opening motion, center distance and envelope Angle. Belt type according to the cross-section shape can be divided into flat belt, V-belt and special belt three categories.

The key points in application are: calculation of transmission ratio; Belt stress analysis and calculation; Allowable power of a single V-belt.

Advantages: suitable for two shaft center distance larger transmission; The belt has good flexibility, which can ease the impact and absorb the vibration. Skidding during overload to prevent damage to other parts; Simple structure and low cost.

Disadvantages: the outer size of the transmission is large; Need tensioning device; Due to slippage, a fixed transmission ratio cannot be guaranteed; The life of the belt is short; The transmission efficiency is low.

4. Chain drive

Including: active chain, driven chain, ring chain.

Compared with gear drive, chain drive has the following characteristics: lower requirements for manufacturing and installation accuracy; When the center distance is large, the transmission structure is simple; Instantaneous chain speed and instantaneous transmission ratio are not constant, and the transmission smoothness is poor.

5. Wheel train

The gear train is divided into two types: fixed shaft gear train and turnover gear train.

The ratio of the angular speed (or speed) of the input shaft to the output shaft in the gear train is called the gear ratio. Equal to the ratio of the product of the number of teeth of all driven gears in each pair of engaging gears to the product of the number of teeth of all driving gears.

In the epicyclic gear system, the gear with the axis position change, that is, the gear with both rotation and revolution, is called the planetary wheel, and the gear with the axis position fixed is called the center wheel or the sun wheel.

The transmission ratio of the epicyclic gear train can not be calculated directly by the method of solving the transmission ratio of the fixed shaft gear train. The relative velocity method (or inversion method) must be used to transform the epicyclic gear train into an imaginary fixed shaft train.

The main features of the gear train are: suitable for transmission between two shafts that are far apart; Can be used as a transmission to achieve variable speed transmission; Large transmission ratio can be obtained; The synthesis and decomposition of motion are realized.

Electric Drive

1.High accuracy

Servo motor as a power source, by the ball screw and synchronous belt composed of simple structure and high efficiency transmission mechanism. It has a repeatability error of 0.01%.

2.Save energy

The energy released during the deceleration phase of the working cycle can be converted into electrical energy for reuse, thus reducing the operating cost, and the connected electrical equipment is only 25% of the electrical equipment required for hydraulic drive.

3.Precision control

According to the set parameters to achieve accurate control, with the support of high-precision sensors, measuring devices, computer technology, can greatly exceed the control accuracy of other control methods can achieve.

4.Improve environmental protection

Due to the reduction of the use of energy varieties and its optimized performance, the pollution source is reduced, the noise is reduced, and the environmental protection work of the factory is provided with a better guarantee.

5.Reduce noise

Its operating noise value is less than 70 decibels, which is about 2/3 of the noise value of the hydraulic driven injection molding machine.

6.Save costs

This machine eliminates the cost of hydraulic oil and the trouble caused, no hard pipe or soft throat, no need to cool hydraulic oil, greatly reducing the cost of cooling water.

Hydraulic drive

Advantages:

1. from the structural point of view, the output power per unit weight and output power per unit size in the four types of transmission mode is the force pressure group, there is a large torque inertia ratio, in the case of the transmission of the same power, the hydraulic transmission device is small, light weight, small inertia, compact structure, flexible layout.

2. from the performance point of view, speed, torque, power can be stepless adjustment, fast response, can quickly reverse and change speed, wide speed range, speed range up to 100:l to 2000:1; The action is fast, the control and adjustment are simple, the operation is convenient and labor-saving, it is easy to cooperate with the electrical control, and the connection with the CPU(computer) is easy to realize the automation.

3. from the use and maintenance point of view, the self-lubrication of the components is good, easy to achieve overload protection and pressure preservation, safe and reliable; Components are easy to realize serialization, standardization and generalization.

4. all the equipment using hydraulic technology is safe and reliable.

5. economic: the plasticity and variability of hydraulic technology is very strong, can increase the flexibility of flexible production, and easy to change and adjust the production process, hydraulic components relatively speaking, the manufacturing cost is not high, and the adaptability is strong.

6. Hydraulic pressure is easy to combine with new technologies such as microcomputer control, forming the integration of "machine-electric-liquid-optical" has become the trend of world development, and it is easy to realize digitalization.