0102030405

Motor Shaft Failure, Is the Manufacturer or the User's Problem?

2024-06-27 10:43:06

The shaft is the key to the docking of the motor product and the device being dragged, and carries the heavy task of the kinetic energy conversion of the motor. During the use of the motor, there will always be some cases of broken shaft failure.

The fracture position of the shaft, which we have talked about many times in the previous article, is the shaft extension root, the bearing position of the drive end, and the plate end position of the welded shaft.

This article provides a few examples of broken shaft failure pictures, you can find their own views, but also can learn some experience and lessons.

Quality control of the shaft itself

Starting from the theoretical analysis, we should start from the diameter control of the shaft, and try our best to avoid the sudden change of the diameter. The measures to be taken lie in the selection of the design size on the one hand, and the guarantee of the processing technology on the other hand, that is, the stress relief measures to avoid the occurrence of such problems

For special purpose motors, the shaft should be made of special materials if necessary, through the improvement of forging or turning methods to achieve a smooth change in the diameter of the shaft, so as to reduce the steps on the shaft and effectively reduce the stress problem.

For welded shafts, we can prevent such problems by welding process control and necessary stress relief measures.

Correlation analysis

For motor products, the shaft belongs to the rotor part, is a rotating body, the relative guarantee of physical space is very important, which involves the motor stator part of the frame, iron core, end cover radial size control, as well as bearing selection and installation. When the rotor is fixed with different centers, it is easy to have the problem of uneven unilateral magnetic pull, which directly leads to motor vibration and low-frequency electromagnetic sound, and the problem of cleaning the bore occurs in serious cases. In view of the axial and radial limit of the bearing to the rotor, when the unilateral magnetic pull is not uniform, the rotating shaft will naturally be affected by the radial force, which aggravates the fracture problem of the shaft.

The inadequacy of the transmission process

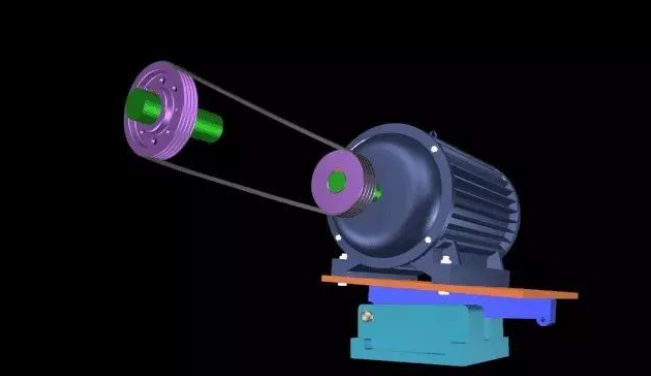

In the previous article we talked about the installation and transmission of the motor, if the conditions allow, especially for high-power motors, it is not recommended to use belt drive, because relative to the coupling drive, the transmission increases the bending moment of the shaft. If necessary, the motor shaft and bearing system should be improved. There was a crushing processing enterprise, equipment and motor using pulley drive, but from time to time there will be a broken shaft quality failure, in response to this problem, motor manufacturers through the quality improvement of the shaft, and the original deep groove ball bearings adjusted to cylindrical roller bearings, such problems have been better controlled. Compared with deep groove ball bearings of the same dimensions, cylindrical roller bearings are line contact, and ball bearings are point contact, and the carrying capacity of line contact is of course large; Secondly, the number of rolling elements of cylindrical roller bearings is more than that of deep groove balls, and the carrying capacity is of course large.

For the transmission of the motor, especially the field construction, due to some practical problems objectively existing in the installation base, special attention should be paid during the installation and use of the motor. For this kind of problem, when the problem occurs, whether it is the motor manufacturer or the user, it should be based on the data for objective analysis and improvement, especially for the problem that has rules to follow, it is relatively easy to solve.