0102030405

Motor energy efficiency improvement program

2024-06-27 10:43:06

(1) Expand the green supply of energy-efficient motors

1. Accelerate the improvement of green design capabilities. Actively promote the green design of the whole life cycle of the motor system, and encourage systematic and innovative design such as motor performance optimization, high efficiency of the iron core, and lightweight of the housing to comprehensively improve the energy and resource utilization efficiency of the motor products. Optimize the size and line of fan and pump impeller, and vigorously develop a new generation of fan and pump products that are reasonably matched with high-efficiency and energy-saving motors.

2. Vigorously promote the green upgrading of basic materials and components. Accelerate the innovation and upgrading of key supporting materials for high-efficiency and energy-saving motors, and improve the green level of materials such as high-performance electromagnetic wire, high-magnetic induction and low-loss cold-rolled silicon steel sheet, light rare earth permanent magnet, water-based insulating paint and anti-rust paint, and low-volatile solvent-free impregnating paint. Optimize and upgrade the production process equipment and molds of energy-saving motors, accelerate the application of lost mold casting, near net forming and other technologies, and improve the green production capacity of frame and end cap castings.

3. Continue to improve the green manufacturing level of motor products. Accelerate the promotion of stator sinusoidal winding, rotor punching slot cutting air gap, rotor low die casting aluminum, rotor closed slot and other technologies to improve the production support capacity of energy-saving motors. Speed up the application of fixed rotor punching progressive die high-speed stamping, automatic swing stamping, automatic pressing, automatic painting, automatic wire winding and other equipment to improve the automation level of motor production. Encourage the use of energy management, electrical energy feedback motor test and other energy metering monitoring and optimal utilization systems.

(2) Expand the industrial chain of energy-efficient motors

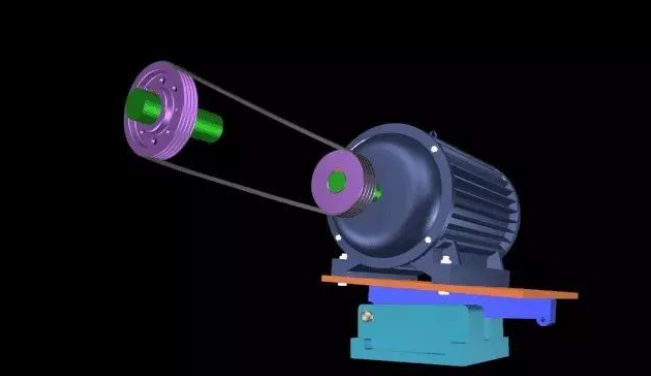

4. Accelerate the technological innovation of motor system. Promote the research and development of energy-saving technologies for motor systems such as fans, pumps and compressors, accelerate the application of quadratic torque characteristic loads such as centrifugal fans and pumps to match high-efficiency and energy-saving motors, low-speed and high-torque direct drive technology, high-speed direct drive technology, servo drive technology, etc., to improve the efficiency and quality of motor systems. Further optimize the motor control algorithm and control performance, speed up the breakthrough of permanent magnet motor efficiency optimal control and position sensorless reluctance motor parameter accurate identification technology.

5. Actively implement efficient motor remanufacturing. Promote the improvement of waste motor recycling system, encourage waste motor recycling, motor efficient remanufacturing and motor use enterprises to strengthen cooperation, innovation motor efficient remanufacturing operation mode. Strengthen the research of remanufactured motor and load matching technology, and promote the construction of quality control, process equipment and testing capacity of remanufactured motor. Organize the identification of high-efficiency motor remanufacturing products, further standardize the production of remanufactured motors, and guide the application of remanufactured motor products.

(3) Accelerate the promotion and application of energy-efficient motors

6. Carry out energy-saving transformation of stock motors. Key industries such as iron and steel, nonferrous metals, petrochemicals, chemicals, building materials and textiles are encouraged to carry out energy-saving diagnosis of energy-using equipment, and assess the promotion and application potential of advanced energy-saving technologies and equipment based on the energy efficiency level and operation and maintenance of equipment. We will guide enterprises to update and upgrade key energy-using equipment such as motors, give priority to the selection of high-efficiency and energy-saving motors, and speed up the elimination of backward and inefficient motors that do not meet the requirements of current national energy efficiency standards. Enterprises are encouraged to carry out matching energy-saving transformation and operation control optimization of inefficient fan, pump, compressor and other motor systems.

7. Increase the application of energy-saving motors. Subdivide the load characteristics and different working conditions, and encourage the use of motors with level 2 energy efficiency and above for general equipment such as fans, pumps, compressors, and machine tools. According to the variable load operation condition, the frequency conversion speed regulating permanent magnet motor with 2 level energy efficiency and above is promoted. For transmission systems using transmissions and couplers, the use of low-speed direct drive and high-speed direct drive permanent magnet motors is encouraged. Vigorously develop permanent magnet external rotor electric roller, integrated screw compressor and other motor and load equipment structural integration design technology and products

(4) Promote the intelligent and digital improvement of the motor system

8. Accelerate the promotion of intelligent motor system. Promote intelligent and automated motor production and manufacturing, and encourage the application of automatic wiring, wire winding, casing combination milling and drilling processing, automatic stamping, automatic assembly, automatic testing and other equipment. Promote the application of Internet unified identification and analysis technology for motor products, and explore the intelligent tracking management of the whole life cycle of motors. Research on energy efficiency optimization model and intelligent algorithm of motor system was carried out to improve the mechanism model of motor fault diagnosis. Accelerate the application of motor intelligent sensor series products, multi-sensor data fusion technology, etc., and promote the integration of motor system operation data acquisition, calculation, storage and communication.

9. Collaborative propulsion motor system digitization. Encourage the establishment of digital collaborative manufacturing platforms, promote the efficient interaction of data between production planning, process technology, material distribution, equipment monitoring and maintenance, quality control, logistics tracking and other systems, and centralized control of process manufacturing and production control data. Promote the data monitoring and information sharing of all aspects of the industrial chain such as the research and development and design of motor products, production and manufacturing, and enterprise operation and maintenance, and encourage the cloud of motor system equipment.

Third, safeguards

1. Strengthening organization and implementation. Provincial industry and information technology, market supervision departments according to this plan, combined with the actual work measures to strengthen guidance and services. Make full use of existing funding channels such as energy conservation and emission reduction to support key projects to improve motor energy efficiency. Relevant industry associations and enterprises are encouraged to formulate special work plans in accordance with the objectives and tasks set out in this plan and in light of the actual conditions of the field and the enterprise, and to promote the implementation of the plan as a whole.

2. Strict supervision and administration. Strictly implement the national energy efficiency standards such as the "Motor Energy Efficiency Limit Value and energy efficiency Grade" (GB 18613-2020), strengthen the inspection of the conformity of energy efficiency labels, and prohibit the purchase, use and production of motor products that are eliminated by the state. Organize the implementation of special industrial energy-saving supervision, carry out energy efficiency supervision of motor users, and urge enterprises to eliminate motor products that do not meet the mandatory energy efficiency standards according to law with relevant departments.

3. Strengthening energy conservation services. Give full play to the role of industrial energy conservation and green development evaluation center and green manufacturing system solution suppliers, actively carry out special energy-saving diagnosis of motor systems, and put forward energy-saving transformation suggestions. Actively cultivate third-party energy saving service institutions, develop market-oriented models such as comprehensive energy services and contract energy management, promote the transformation of motor energy saving and efficiency, promote motor energy saving certification, and increase the supply of energy-saving motor products.

(4) Active publicity and guidance. Make full use of green manufacturing public service platform, energy-saving publicity week and other channels to further increase the publicity and promotion of energy-efficient motors. Organize relevant industry associations and research institutions to carry out a series of activities of high-efficiency energy-saving motors into enterprises under the framework of the "Energy saving Service into enterprises" activity, and coordinate the implementation of technical exchanges, business training, standard promotion and supply and demand docking. Actively carry out international exchanges and cooperation in the fields of motor energy efficiency standards benchmarking and mutual recognition, advanced technology of motor systems, and efficient motor remanufacturing.