0102030405

Analysis of box structure motor and its advantages and characteristics

2024-06-27 10:43:06

Most of the domestic motor manufacturers, cast iron frame as the first choice, but with the continuous extension of the national environmental protection policy box frame will be extended down from large specification products, especially for small batch products with special requirements, box frame can just make up for the time cycle and cost of cast iron frame mold. Compared with the corrugated steel plate frame, the box frame is widely used in our country's large motor, today we will talk about the box frame structure of the motor.

Since the late 1950s, the United States Westinghouse (WH) company first developed the F/A series of box-type structure motor, and then the box-type structure is widely used in foreign countries in medium and large AC and DC motors. In China, since the 1970s, the box-type structure motor has been developed, therefore, in recent years, the new design of the basic series of medium-sized high-voltage induction motor, all use the box-type structure.

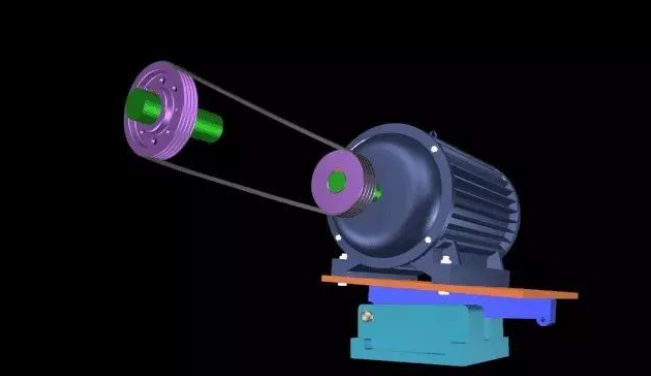

There are many specific types of box-type structure, and the shape, processing and assembly methods of its parts are different. The frame of box-type structure is usually welded with steel plate, and the other main components are outer cover, base, stator, rotor and bearing. Because the outer cover does not bear the load, it only plays the role of protection and cooling system, and can be made of steel plate with a thickness of about 2mm. The cover can be a whole, or can be composed of two parts. The base to withstand the gravity and various forces or torque of the entire motor, requiring a high strength and stiffness, usually made of thicker steel welded (can also be cast). The stator is an independent component completely separate from the base and the outer cover, and the whole goes into the base. The shaft can be supported by hydraulic bearings or plain bearings, which are installed in separate bearing seats, which are divided into upper and lower halves on the shaft center line for easy disassembly.

Main advantages of box structure

First of all, the components are highly versatile, not only between the same series of motors can be common, synchronous motors and induction motors can also be common, such as the aforementioned Westinghouse F/A series. In the 6 specifications of large rolled DC motor produced by Siemens technology introduced in China in the early 1980s, in addition to bearings, stator, rotor, brush holder, end cover, bottom frame, etc., all are common.

Secondly, for the motor with a half cover, just using a different cover can easily derive a variety of protection types and different cooling systems of the motor. In this way, as long as the local structure of the motor cover is changed, the needs of different users can be met to shorten the production cycle and reduce production costs.

Third, make small and medium-sized motor stator core can use external pressure mounting process. In this way, not only can the stator core pressing down, painting and base, outer cover processing, divided into two production lines at the same time, shorten the production cycle, and, after the externally pressed stator core down the line, easy to use the integral, vacuum, pressure coating (VP1) process, improve the insulation quality, but also reduce the winding temperature rise. In addition, when the stator core is stacked, if the suitable tire expansion is used, the processing of the inner circle of the core can be completely eliminated, which is usually grinding the inner circle on the vertical car, and the additional loss of the stator teeth is reduced.

Fourth, less mechanical processing, convenient offline, easy to disassemble. The box-type steel frame is much lighter and aesthetically pleasing than the traditional cast iron frame. And because the foundry covers an area of large, poor working conditions, the pollution of the environment is more serious and the cost of high control factors, but also to promote the development of box-type steel plate motor.

Usually, the vibration absorption performance of the box steel frame is worse than that of the cast iron frame, so the design and manufacture should pay attention to reducing the vibration and noise of the motor.